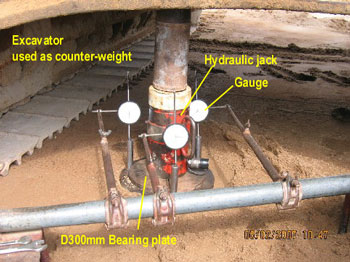

Plate Bearing Test

The plate bearing test is carried out to establish the bearing capacity of material being placed or existing excavated material, this could be for design values of structures, runways or crane bases.

The plate bearing test can also be used to establish the in-situ CBR Value.

The test shall be carried out in general accordance with BS 1377: Part 9 1990 'in-Situ Tests'.

A circular plate having a maximum diameter of 300 - 600mm shall be used. Varying diameters can used depending of the maximum stone size within the material.

Plate Bearing Test 2Excavate to the test level as quickly as possible to minimise the effects of stress relief, particularly in cohesive fills. A mechanical excavator may be used provided that the excavator bucket does not have teeth and the last 100mm depth of excavation is carried out carefully by hand.

Carefully trim off and remove all loose material and any embedded fragments so that the area for the plate is generally level and as undisturbed as possible.

Protect the test area and the apparatus from moisture changes, sunlight and the effects of adverse weather as soon as the test level is exposed and throughout the test.

The area for test shall be flat and free from loose material, a thin layer (10 to 15mm thick) of dry clean silica sand shall be used to fill any surface voids. to produce a level surface on which to bed the plate.

Set up the loading and deflection, measuring systems so that the load is applied to the plate without eccentricity and the deflection system is outside the zone of influence of the pattachments.ziplate. During these operations a small seating load may be applied to the plate to enable adjustments to be made: this seating load shall be less than 5kN/m2.

The load shall be applied in five increments. Settlement reading will be taken at 0.50 minute intervals for the first 2 minutes, and 1 minutes intervals thereafter, until detectable movement of the plate has stopped, i.e. until the average settlement rate is less than 0.02mm per 5 minute interval.

At each increment the pressure shall be maintained as near as possible constant.

After the final test increment has been completed, the pressure in the hydraulic pump shall then be released and the settlement of the plate allowed to recover. When the recovery is essentially complete, the residual settlement value shall be recorded.